Kwiminyaka yakutshanje, kukho uphuhliso olukhawulezayo lwefiber-reinforcediicomposites thermoplastic kunye ne-thermoplastic resins njenge-matrix, kwaye kukho ukwanda kophando kunye nophuhliso lwezi zixhobo eziphezulu zokusebenza kwihlabathi jikelele. Iingxube ze-Thermoplastic ziyi-composites ezenziwe ngeepolima ze-thermoplastic ezifana ne-polyethylene (PE), i-polyamide (PA), i-polyphenylene sulfide (PPS), i-polyetherimide (PEI), i-polyether ketone (PEKK) kunye ne-polyether ether ketone (PEEK) njenge-matrix kunye neentlobo ezahlukeneyo eziqhubekayo / eziqhubekayo. iifibers (umz. iifibers zekhabhon, iifibers zeglasi, iifibers zearamid, njl.njl.

Iicomposites ze-Thermoplastic grease-based gries ikakhulu yi-Long Fiber reinforced Thermoplastics (LFT), i-MT iiteyiphu eziqhubekayo ezifakwe ngaphambili kunye neglasi yeglasi eyomeleziweyo yeThermoplastics(CMT).

Ngokutsho kokusetyenziswa kweemfuno ezahlukeneyo, i-matrix ye-resin ine-PPE.PAPRT, i-PELPCPES, i-PEEKPI, i-PA kunye nezinye iiplastiki zobunjineli be-thermoplastic.

I-matrix ye-Thermoplastic

I-matrix ye-Thermoplastic luhlobo lwemathiriyeli ye-thermoplastic eneempawu ezilungileyo zoomatshini kunye nokumelana nobushushu obunokusetyenziswa kuluhlu olubanzi lweemveliso zoshishino. I-matrix ye-Thermoplastic inamandla amakhulu, ukuxhathisa ubushushu kunye nokuxhathisa okulungileyo kokuhlwa.

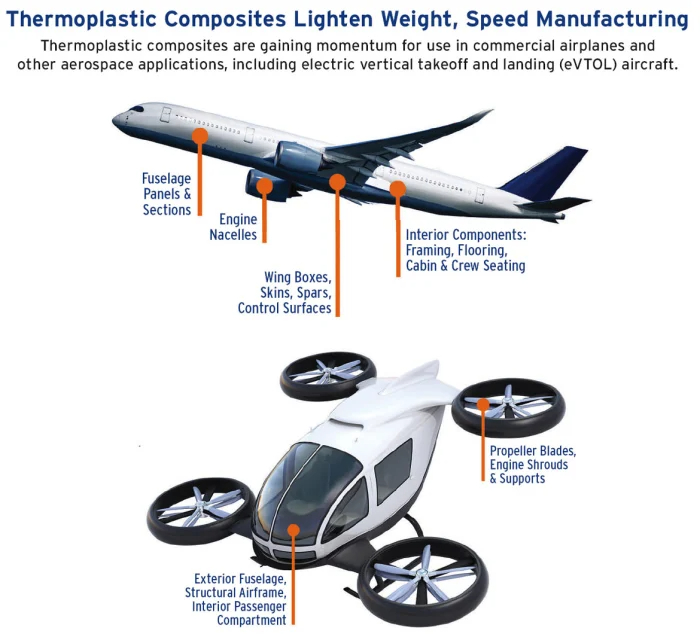

Iintlaka ze-thermoplastic ezisetyenziswa ngoku kwizicelo ze-aerospace ubukhulu becala bubushushu obuphezulu, i-high-performance resin matrices, kuquka i-PEEK, i-PPS kunye ne-PEI, apho i-amorphous PEI isetyenziswa ngokuqhelekileyo kwizicelo ze-aerospace kune-semi-crystalline PPS kunye ne-PEEK, apho i-PEI ye-amorphous. inezicelo ezininzi kwizakhiwo zenqwelomoya kune-semi-crystalline ye-PPS kunye nobushushu obuphezulu bokubumba iPEEK ngenxa yobushushu obuphantsi bokusebenza kunye neendleko zokusetyenzwa.

Iiresin ze-Thermoplastic zineempawu ezingcono zoomatshini kunye nokumelana neekhemikhali, ubushushu benkonzo ephezulu, ukomelela okuphezulu kunye nokuqina, ukomelela okugqwesileyo kokwaphuka kunye nokunyamezela umonakalo, ukumelana nokudinwa okugqwesileyo, ukukwazi ukubumba iijiyometri ezintsonkothileyo kunye nezakhiwo, ukuguquguquka kwe-thermal conductivity, ukuphinda usebenziseke, uzinzo oluhle kwiindawo ezirhabaxa. , ukubumba okuphindaphindwayo, kunye ne-weldability, njl.

Iimbumba eyenziwe nge-resin ye-thermoplastic kunye nezinto eziqinisayo zineenzuzo ezininzi ezifana nokuqina, ukuqina okuphezulu, ukuchasana kwempembelelo ephezulu kunye nokunyamezela umonakalo; i-fiber prepreg ayifuni kugcinwa kwiqondo lokushisa eliphantsi kwakhona, ixesha lokugcina elingenasiphelo; umjikelo wokubumba omfutshane, i-weldable, imveliso ephezulu, kulula ukuyilungisa; i-scrap inokuphinda isetyenziswe kwaye isetyenziswe kwakhona; inkululeko enkulu yoyilo lwemveliso, inokwenziwa kwiimilo ezintsonkothileyo, ukuguquguquka okubanzi kokubumba, njl.

Ukuqinisa imathiriyeli

Ngokuqhelekileyo, ubude beefiber ezimfutshane eziqiniweyo zi-0.2 ukuya kwi-0.6 mm, kwaye ekubeni ezininzi iifayili zingaphantsi kwe-70 μm ububanzi, ngoko ke iifayili ezimfutshane zibukeka njenge powder. Iifayibha ezimfutshane ezomeleziweyo ze-thermoplastics ziqhele ukwenziwa ngokuxuba imicu ibe yi-thermoplastics etyhidiweyo. Ubude kunye nokuqhelaniswa okungacwangciswanga kwefiber kwi-matrix kwenza kube lula ukufezekisa ukumanzisa okulungileyo, kwaye iicomposites ezimfutshane zefiber zezona zilula kakhulu ukuzenza xa kuthelekiswa nemathiriyeli eyomeleziweyo emide kunye neqhubekayo, kodwa ngophuculo oluncinci kwiipropathi zoomatshini. Iimbumba zefiber ezimfutshane zikholisa ukubunjwa zibe ziinxalenye zokugqibela ngokubumba okanye iindlela zokukhupha ngenxa yokuba iifiber ezimfutshane zinempembelelo encinci ekuhambeni.

Imihlanganiselwa eyomeleziweyo yefiber ende ziqhelekile malunga ne-20 mm kubude befayibha kwaye zidla ngokulungiswa kusetyenziswa iintsinga eziqhubekayo ezifakwe nentlaka kwaye zisikwe kubude obuthile. Inkqubo esetyenziswa ngokuqhelekileyo yinkqubo yokubumba i-pultrusion, apho ukujikeleza ngokuqhubekayo komxube we-fibers kunye ne-thermoplastic resin iveliswa ngokolula imicu ngokufa okubumba okukhethekileyo. Okwangoku, i-PEEK ye-thermoplastic composites ende ye-fiber-reinforced ikwazi ukufikelela kwiipropati zesakhiwo ezingaphezu kwe-200 MPa ngokuprintwa kwe-FDM kunye ne-modulus engaphezulu kwe-20 GPa, kunye nokusebenza okungcono ngokubunjwa kwenaliti.

Iintsinga kwiicomposites eziqhubekayo zefiber "ziyaqhubeka" kwaye zihamba ngobude ukusuka kwiimitha ezimbalwa ukuya kwiimitha ezingamawaka amaninzi. Imidibaniso yefiber eqhubekayo ifumaneka ngokubanzi njengeelaminates, iiteyiphu zeprepreg, okanye iibraids, ezenziwe ngokufaka i-matrix ye-thermoplastic efunwayo ngeentsinga eziqhubekayo.

Zeziphi iimpawu zemathiriyeli edityanisiweyo ezomelezwe ngeentsinga?

I-Fiber eyomeleziweyo i-composites yi-composites eyenziwe ngokujija, ukubumba okanye iinkqubo ze-pultrusion zokuqinisa izinto zefiber, ezifana ne-glass fiber, i-carbon fiber, i-aramid fiber, njl., kunye ne-matrix. Ngokutsho kwezixhobo ezahlukeneyo zokuqinisa, i-composites ye-fiber-reinforced composites yahlulwe ibe yi-glass fiber reinforced composites (GFRP), i-carbon fiber reinforced composites (CFRP) kunye ne-aramid fiber reinforced composites (AFRP).

Ngenxa yezi mpawu zilandelayo ze-fiber-reinforced composite:

(1) amandla aphezulu kunye nemodyuli ephezulu;

(2) ukuyilwa kwezinto eziphathekayo;

(3) ukuxhathisa okulungileyo kokubola kunye nokuqina;

(4) i-coefficient yokwandiswa kwe-thermal efana nekhonkrithi.

Ezi mpawu zenzaFRP izixhoboinokwanelisa iimfuno zezakhiwo zale mihla ukuya kwisithuba esikhulu, inqaba, umthwalo onzima, ubunzima obulula kunye namandla aphezulu, kwaye isebenze phantsi kweemeko ezinzima, kwaye ihlangabezane neemfuno zophuhliso lolwakhiwo lwezakhiwo zale mihla, ngoko lusetyenziswa ngokubanzi nangakumbi. kwizakhiwo ezahlukeneyo zasekuhlaleni, iibhulorho, oohola bendlela, elwandle, kwizakhiwo ezisebenza ngoxinzelelo olukhulu olwenziwa ngamanzi kunye nezakhiwo ezingaphantsi komhlaba.

Cofa aphangolwazi oluthe kratya malunga nemathiriyeli edibeneyo malungaIGRECHO Fiberglass

Ixesha lokuposa: Mar-31-2023